- Home

- Products

- Particle Processing Plant Dryers

- Fluid Bed Dryer

- Vibrating Fluid Bed Dryer

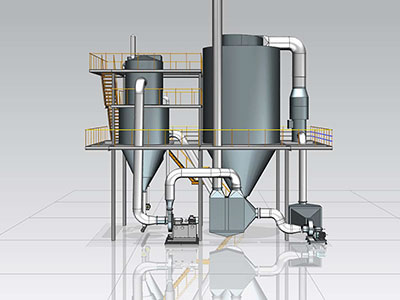

Vibrating Fluid Bed Dryer

Introduction

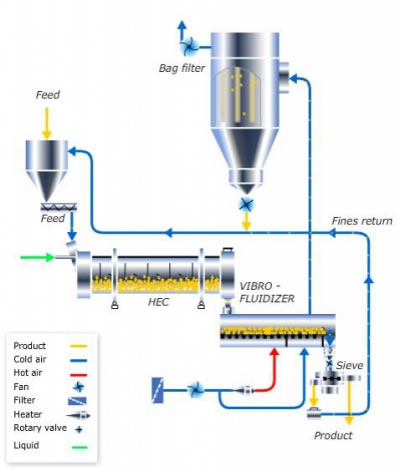

The material enters the vibrating fluid bed dryer from the inlet. And it will continuously move along the horizontal direction under the action of the vibration force. The hot air will pass through the fluid bed from the bottom to realize heat exchanging with wet material. Then the wet air will be discharged from the air outlet after dust removing carried out by rotary separator. And the dry material will be discharged from the material discharge opening.

Application

The vibrating fluid bed dryer is suitable for processing of various disperse powder material in industries such as light industry, chemical industry, food industry, agriculture and sideline industry, pharmaceutical industry etc. It can also be used for material cooling and humidifying.

| Model (ZLG) | Bed area (O) | Inlet Temp. (℃) | Outlet Temp. (℃) | Moisture evaporation(kg/h) | Vibration motor | |

| Model | Power(k w) | |||||

| 3×0.3 | 0.9 | 70-140 | 40-70 | 20-35 | ZDS31-6 | 0.8×2 |

| 4.5×0.3 | 1.35 | 70-140 | 40-70 | 35-50 | ZDS31-6 | 0.8×2 |

| 4.5×0.45 | 2.025 | 70-140 | 40-70 | 50-70 | ZDS32-6 | 1.1×2 |

| 4.5×0.6 | 2.7 | 70-140 | 40-70 | 70-90 | ZDS32-6 | 1.1×2 |

| 6×0.45 | 2.7 | 70-140 | 40-70 | 80-100 | ZDS41-6 | 1.5×2 |

| 6×0.6 | 3.6 | 70-140 | 40-70 | 100-130 | ZDS41-6 | 1.5×2 |

| 6×0.75 | 4.5 | 70-140 | 40-70 | 120-140 | ZDS42-6 | 2.2×2 |

| 6×0.9 | 5.4 | 70-140 | 40-70 | 140-170 | ZDS42-6 | 2.2×2 |

| 7.5×0.6 | 4.5 | 70-140 | 40-70 | 130-150 | ZDS42-6 | 2.2×2 |

| 7.5×0.75 | 5.625 | 70-140 | 40-70 | 150-180 | ZDS51-6 | 3.0×2 |

| 7.5×0.9 | 6.75 | 70-140 | 40-70 | 160-210 | ZDS51 | 3.0×2 |

| 7.5×1.2 | 9 | 70-140 | 40-70 | 200-260 | ZDS51 | 3.0×2 |

| Model (ZLG) | Length | Width | Total width | Height of down bed | Height of upper bed | Total height | Dead weight(kg) |

| 3×0.3 | 3000 | 300 | 1350 | 900 | 430 | 1650 | 1250 |

| 4.5×0.3 | 4500 | 300 | 1350 | 900 | 430 | 1650 | 1560 |

| 4.5×0.45 | 4500 | 450 | 1550 | 950 | 430 | 1700 | 1670 |

| 4.5×0.6 | 4500 | 600 | 1650 | 950 | 430 | 1700 | 1910 |

| 6×0.45 | 6000 | 450 | 1650 | 950 | 430 | 1700 | 2100 |

| 6×0.6 | 6000 | 600 | 1700 | 1000 | 500 | 1700 | 2410 |

| 6×0.75 | 6000 | 750 | 1850 | 1000 | 600 | 1850 | 2340 |

| 6×0.9 | 6000 | 900 | 3000 | 1000 | 600 | 1850 | 3160 |

| 7.5×0.6 | 7500 | 600 | 1850 | 1000 | 600 | 1850 | 3200 |

| 7.5×0.75 | 7500 | 750 | 2000 | 1000 | 600 | 1850 | 3600 |

| 7.5×0.9 | 7500 | 900 | 2100 | 100 | 600 | 1850 | 4140 |

| 7.5×1.2 | 7500 | 1200 | 2500 | 1150 | 800 | 2050 | 5190 |

The vibrating fluid bed dryer produced by JiangSu Xiandao adopts fully enclosed structure so that it can protect the material from secondary pollution caused by contacting with air.

Because of the enclosed structure, the material will be heated uniformly. The heat can be recycled, thus, comparing with the normal drying equipment, it can save energy by 30%.

Data download List for technical parameters of ZLG Series Vibrating Fluid Bed DryerJiangsu Xiandao Drying Sci-Tech. Co., Ltd.

Contact: Johnson Yang

Tel.: +86-519-88909308

+86-519-88900909

Fax: +86-519-88902563