Introduction

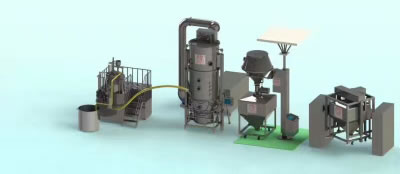

The solid dosage granulating and drying line can effectively combine wet granulation, wet granule-processing, fluidized drying, dry granulation, material transportation and mixing. This line can be used for production of tablet, capsule and granules.

Main application

The solid dosage granulating and drying line is mainly used for solid dosage granulating, coating and food ingredients powder manufacturing.

| Equipment name | Brief introduction | Quantity | Notes |

| High level wet granulator | 160-240kg /pot.3-10Min | 1 | Automatic material feeding and discharging |

| Granule processor | Granule processing: 100-150kg wet granule 4-6 mins | 1 | Matching with high level wet granulating machine |

| Granulator with fluid bed | Drying and granulating: 150-200kg/batch, 10-30Min | 1 | It can adopt negative pressure material feeding. The explosion proof band can be cleaned on line. |

| Elevating granulator | Matching with the granulator with fluid bed which carries out material transferring and granulating; 100-300Kg/batch | 1 | Fixed type |

| Square conical mixer | Mixing volume: 2000L | 1 | Fixed type or elevation type |

Advantages:

The solid dosage granulating and drying line adopts enclosed transporting method so that the granulating and drying are accomplished in one clean room to avoid secondary pollution.

Considering the adaptability of different equipment sets in this system, equipment sets of different types should be selected according to users’ yield. So the optimal performance of the equipment sets can be exercised and the energy and labor resource can be saved.

This line adopts automatic vacuum material feeding unit and sequential lifting device which can replace the traditional manual operation, thus saving labor cost.